Our passion for medical quality is evident in the precision of our products and their positive impact on medical practice. Join us as we explore the future of thoracic surgery together.

Nitinol is a shape memory alloy that exhibits unique properties, such as the ability to return to its original shape after being deformed. The name "Nitinol" is a combination of the words "Nickel Titanium" and "Naval Ordnance Laboratory," referring to the laboratory of the United States Navy where the alloy was first discovered.

The primary composition of Nitinol is a binary alloy of nickel and titanium. This alloy exhibits a martensitic phase transition, which is responsible for its shape memory properties. The alloy can exist in two main crystalline phases: the austenitic phase, which is its original form, and the martensitic phase, which is a deformed form. When Nitinol is heated beyond a certain temperature called the "transition temperature," it transitions from the martensitic phase to the austenitic phase and returns to its original shape.

Innovation fuels our every endeavor. At Adaptia, we push the boundaries of what's possible in thoracic surgery, constantly exploring new technologies and techniques to revolutionize patient care. From pioneering 3D-printed supports to advanced surgical devices, our commitment to innovation drives us to deliver cutting-edge solutions that set new standards in the field. Join us as we shape the future of thoracic surgery together.

Our dedication to research is at the core of everything we do. At Adaptia, we invest heavily in pioneering research initiatives to advance the field of thoracic surgery. Our team of experts works tirelessly to explore new frontiers, uncover breakthroughs, and develop innovative solutions that enhance patient outcomes. Through collaboration with leading medical institutions and ongoing commitment to scientific excellence, we strive to push the boundaries of possibility and shape the future of healthcare. Join us on our journey of discovery as we continue to drive progress and innovation in thoracic surgery research.

Our flexibility lies in our ability to adapt and evolve to meet the ever-changing needs of our clients and the medical industry. At Adaptia, we understand that every situation is unique, and we pride ourselves on our agility and versatility in finding solutions. Whether it's customizing products to fit specific patient requirements or adjusting our approach to meet shifting market demands, we embrace flexibility as a cornerstone of our business philosophy. With Adaptia, you can trust that we will always be responsive and adaptable, ensuring that we deliver the right solutions at the right time.

Made from Nitinol (Ni-Ti), this system offers unparalleled advantages over traditional implants crafted from special steel.

Biocompatibility: Ares-PE is non-toxic and completely biocompatible, ensuring optimal compatibility with the human body. This feature makes it superior to implants made from special steel.

Ease of Removal: Unlike implants that integrate with bone tissue (osteointegrate), Ares-PE does not, making subsequent removal significantly easier and less invasive.

Safety: Extensive in vivo and in vitro studies conducted by leading university research institutes, along with long-term clinical experience, confirm the safety of Ares-PE. It does not induce cancerogenic phenomena, providing peace of mind to patients and healthcare professionals alike.

Diagnostic Compatibility: Ares-PE does not pose challenges with image diagnosis techniques such as CT scans and MRIs. Unlike ferromagnetic implants, it does not interfere with imaging, ensuring accurate diagnostic evaluations.

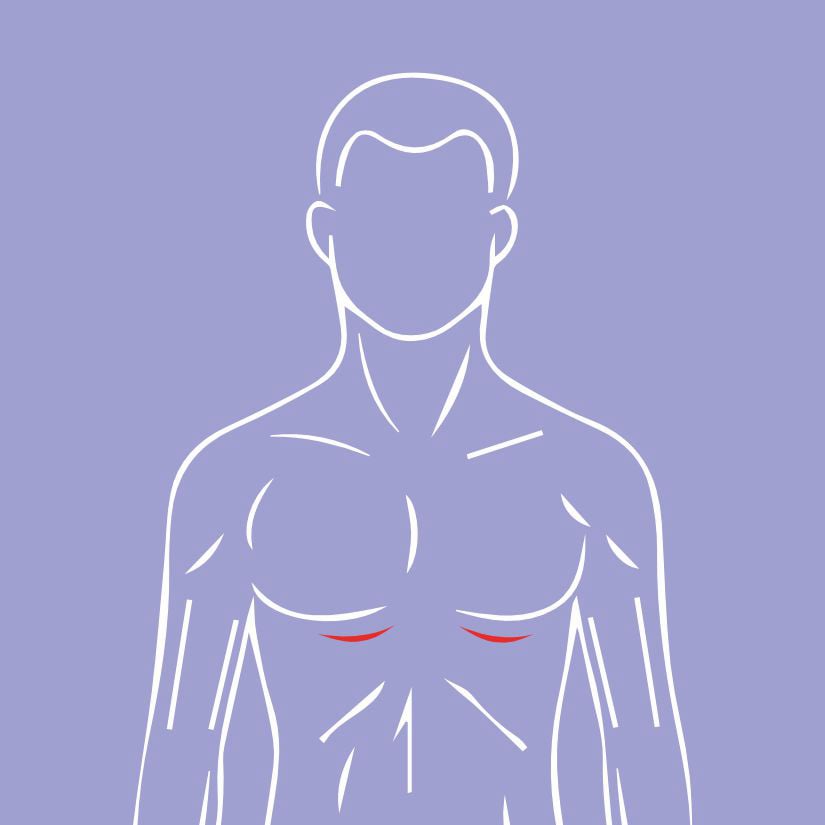

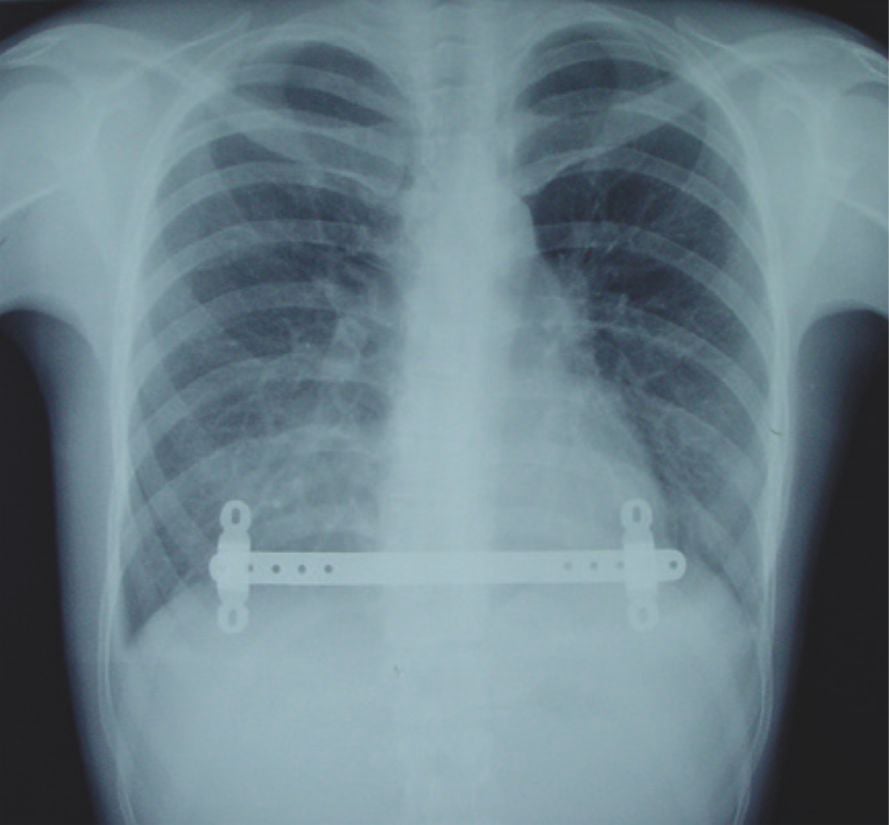

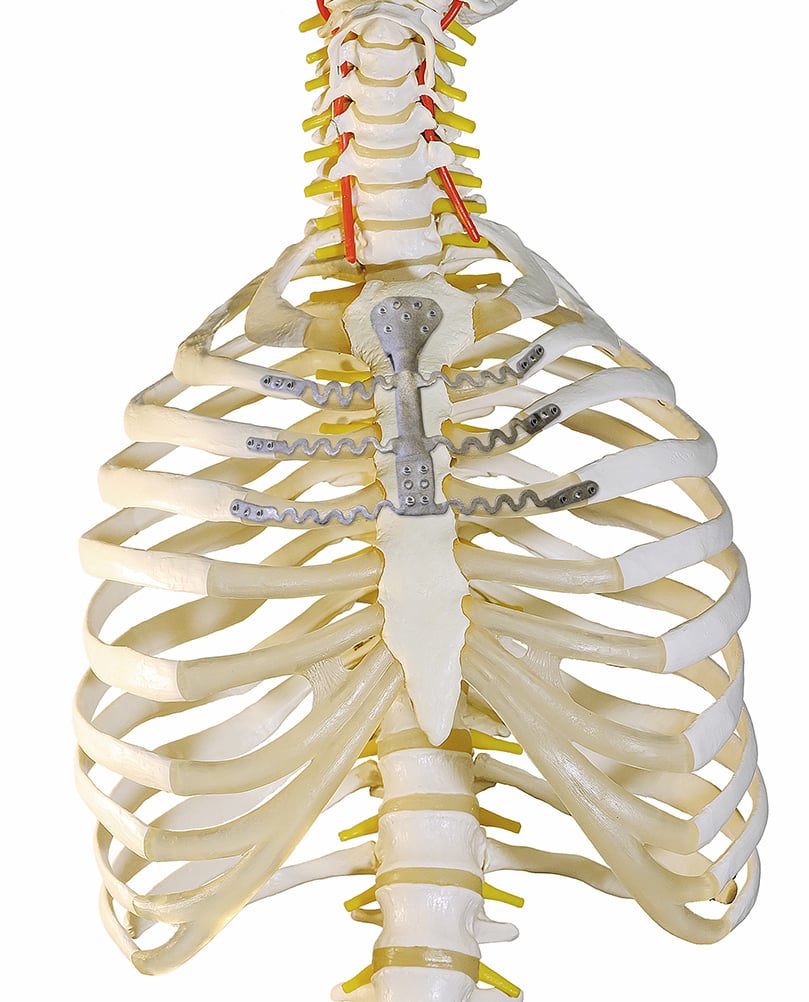

The Nitinol Pectus Excavatum System Ares-PE represents a new standard in medical implant technology, offering superior performance, safety, and compatibility for patients undergoing treatment for pectus excavatum.

The Nitinol Pectus Excavatum System Ares-PE by Adaptia offers unique properties that make it an exceptional choice for semi-rigid fixations in the treatment of pectus excavatum.

Super Elasticity and No Elastic Fatigue: Ares-PE is super elastic and does not experience elastic fatigue, ensuring long-term durability and reliability in semi-rigid fixations.

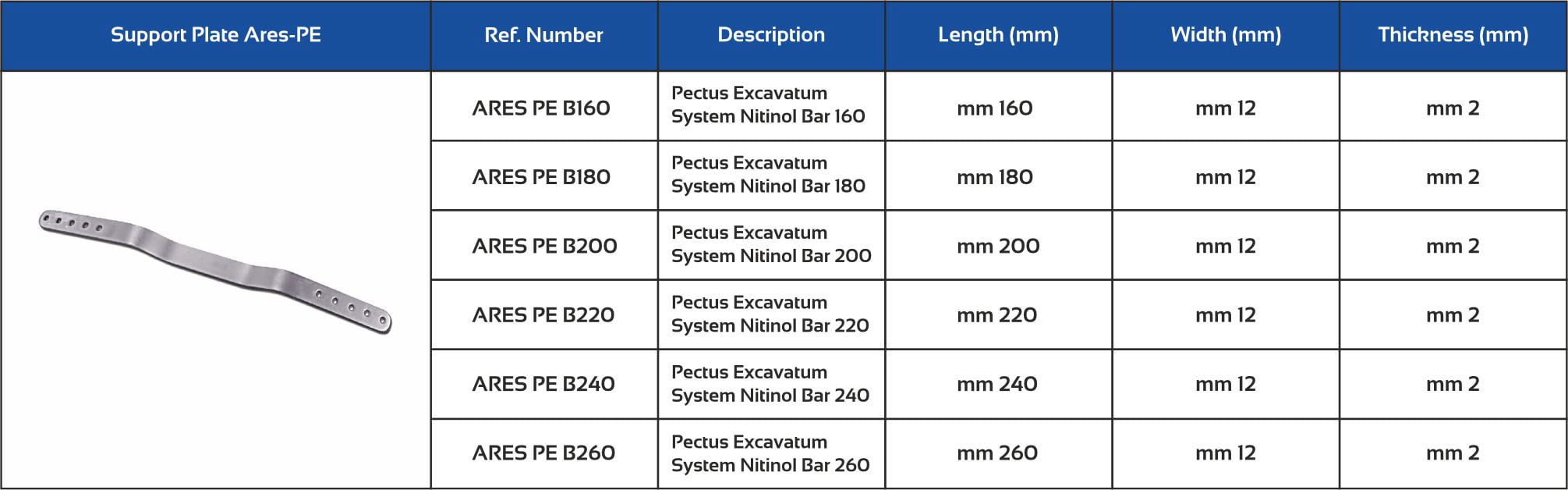

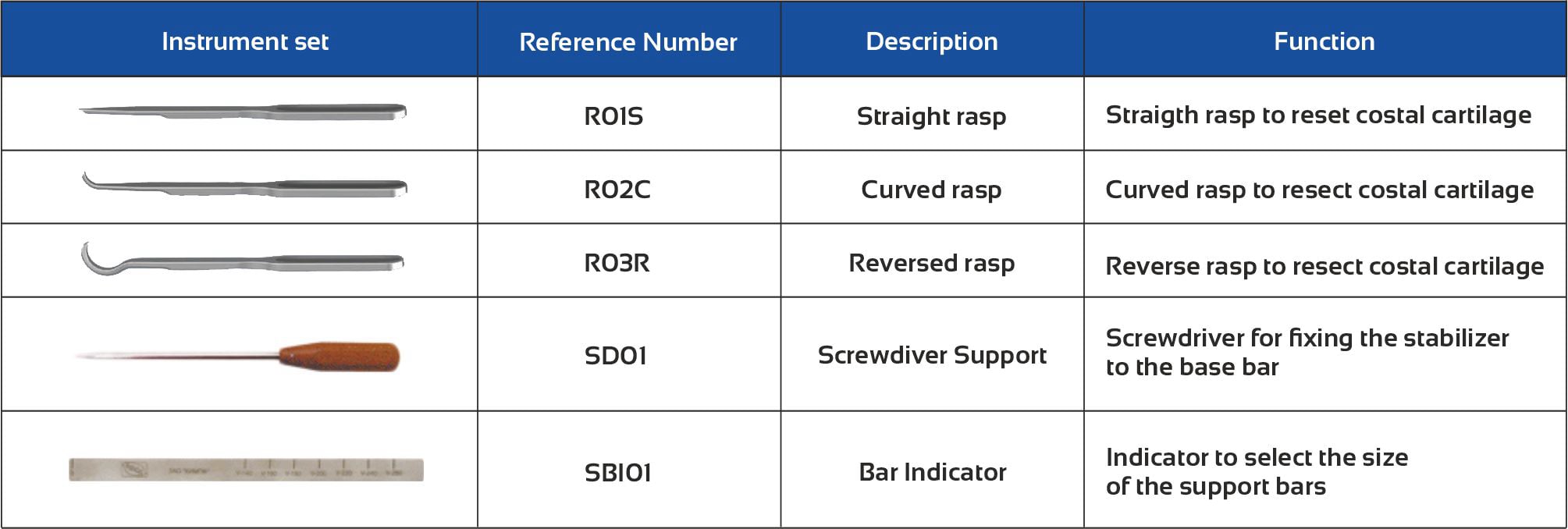

Nitinol Pectus Excavatum System Ares-PE: This system is crafted from a Nitinol (Ni-Ti) alloy with innovative features. It becomes malleable at temperatures between 0°C and 5°C, facilitating easier surgical application. Its memory effect, activated at predetermined higher temperatures, enables dynamic and continuous exertion of strength on the treated area.

Thermoreactive Devices: The use of thermoreactive devices made from Nitinol (Ni-Ti) with shape-memory effect offers an alternative to traditional stainless steel or titanium devices. The lighter weight of Nitinol implants reduces surgical trauma, while semi-rigid compression aids in minimizing immobilization and shortening patient recovery periods.

The Nitinol Pectus Excavatum System Ares-PE demonstrate Adaptia's commitment to innovation and excellence in providing advanced solutions for the treatment of pectus excavatum.

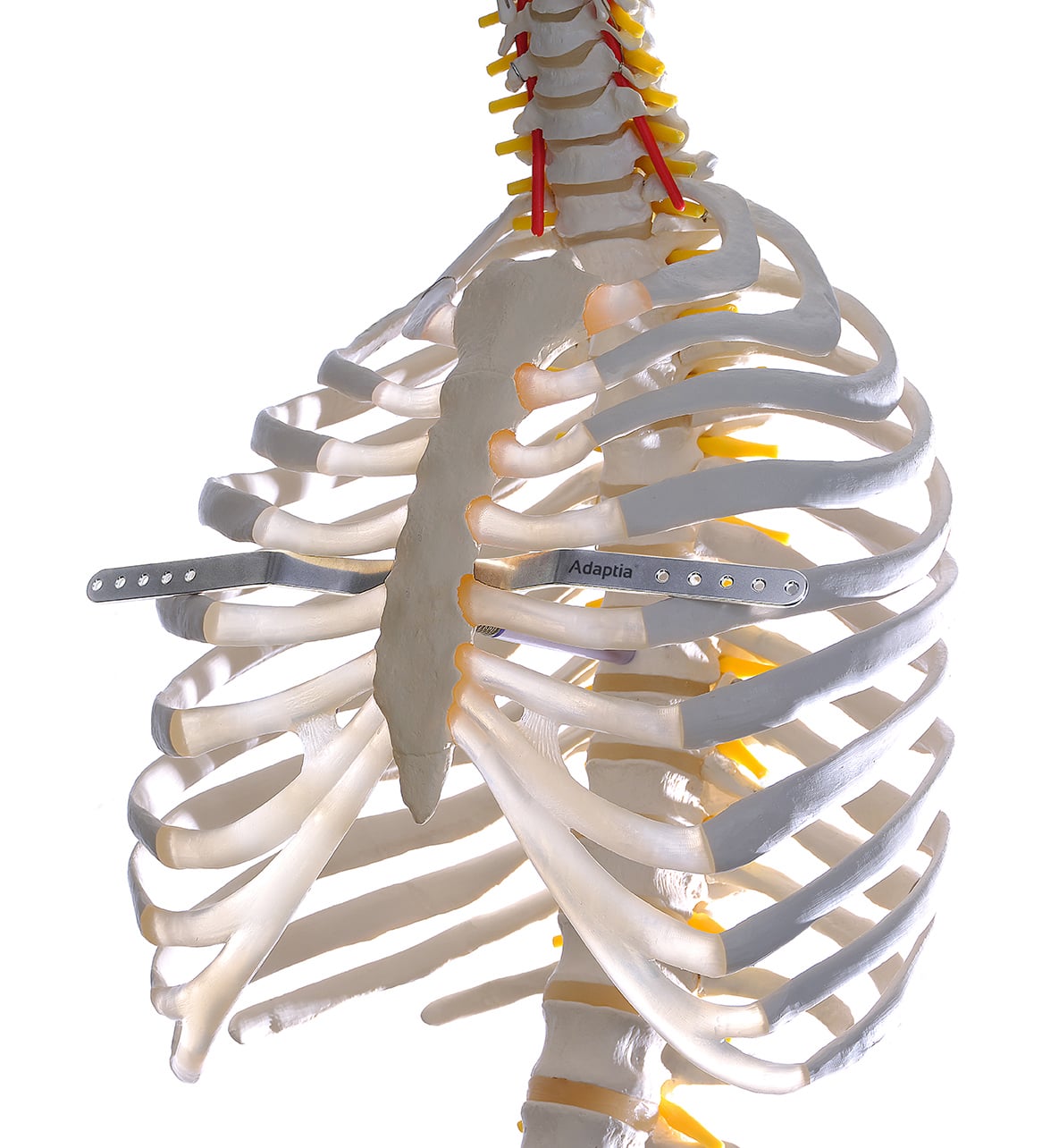

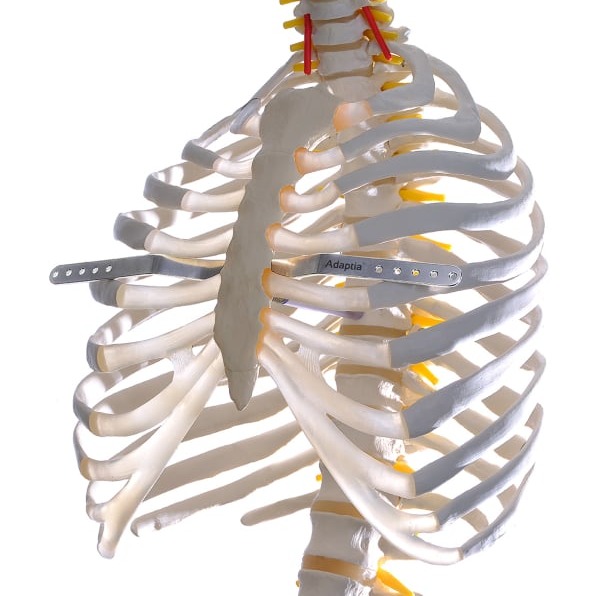

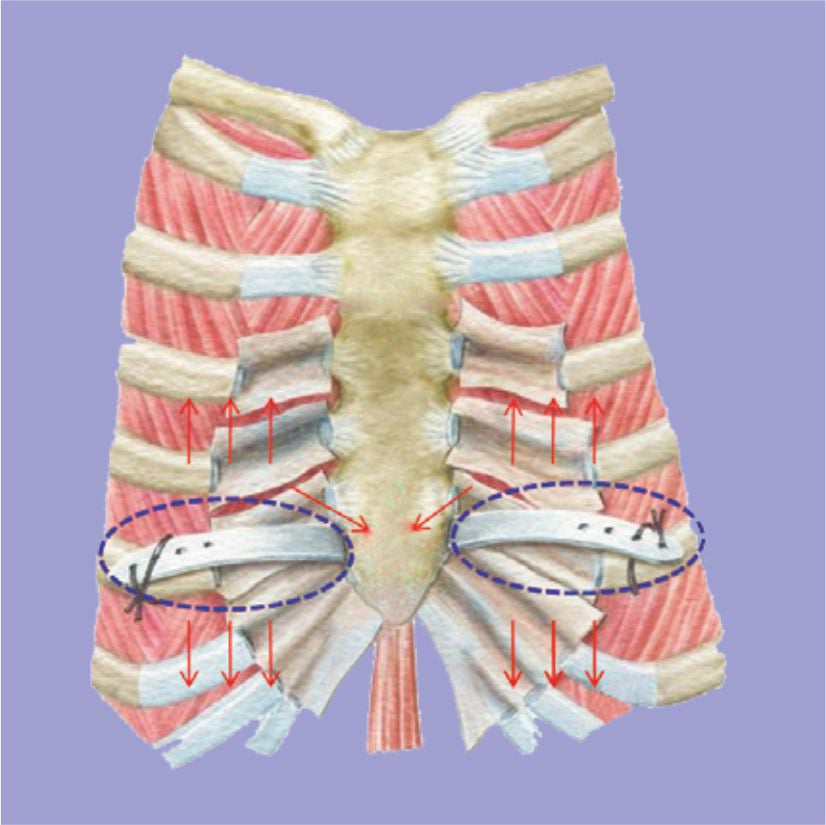

The Nitinol Pectus Excavatum System Ares-PE comprises transverse bars and lateral stabilizers. These components work in tandem to provide comprehensive support and stabilization for the treatment of pectus excavatum. The transverse bars offer structural reinforcement across the affected area, while the lateral stabilizers enhance implant strength and stability.

Together, they form a cohesive system designed to address the unique challenges of pectus excavatum surgery, ensuring optimal outcomes for patients undergoing treatment.

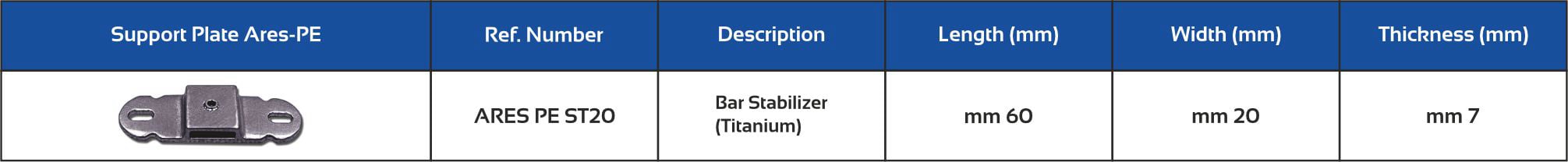

The lateral stabilizer serves as a valuable tool in augmenting the strength of implants.

By providing additional support and reinforcement, it enhances the stability and durability of the implant, particularly in situations where increased strength is required. This component plays a crucial role in optimizing the performance and longevity of the implant, ultimately contributing to the overall success of the surgical procedure.

We work hard to build a future designed to develop and produce innovative medical solutions to improve the health of patients all over the world, basing our commitment on passion and developing our expertise and know-how.

THE ADVANTAGES OF EBM TECHNOLOGY

EBM is the acronym for Electron-Beam Melting and refers to a 3D printing technology in which a high-energy source (consisting of an opportunely concentrated beam of electrons) hits a bed of titanium powder causing it to melt.

DESIGN FREEDOM

Topological optimization

Design of trabecular structures

Structures with a high resistance/weight ratio

Structural continuity between solid and porous structures

EXCELLENT MECHANICAL PROPERTIES

Compliant to ASTM international standards

Microstructure comparable to traditional technologies

HIGH PRODUCTIVITY

Completely recyclable materials

Possibility of production with modular storage towers

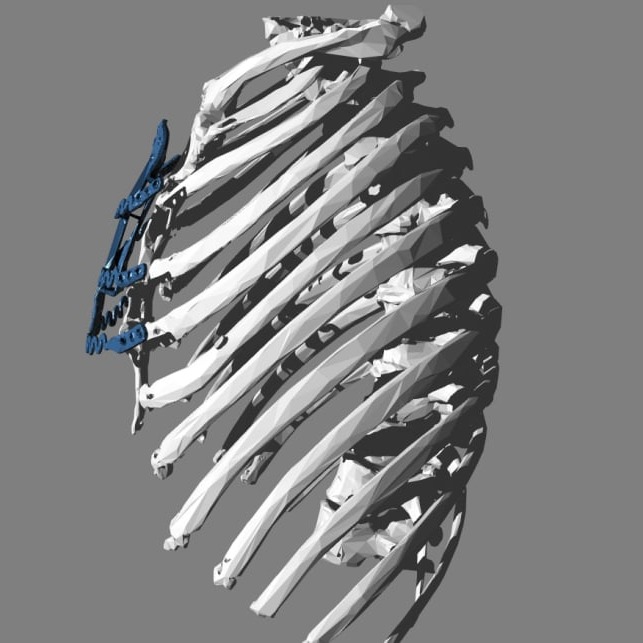

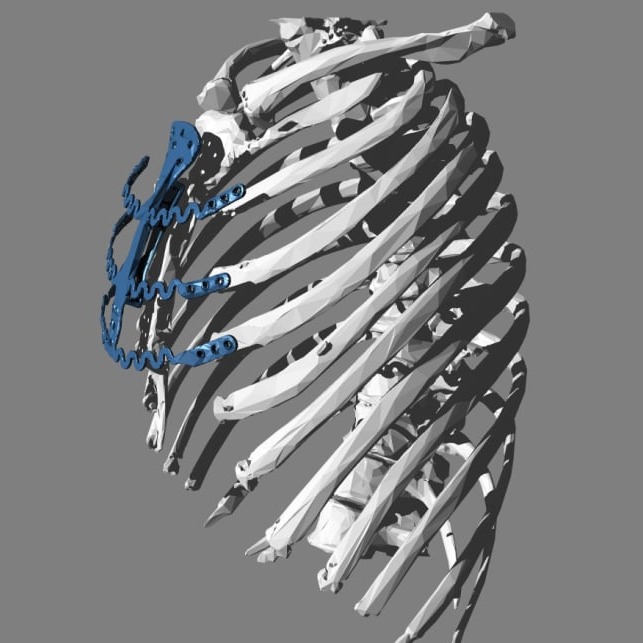

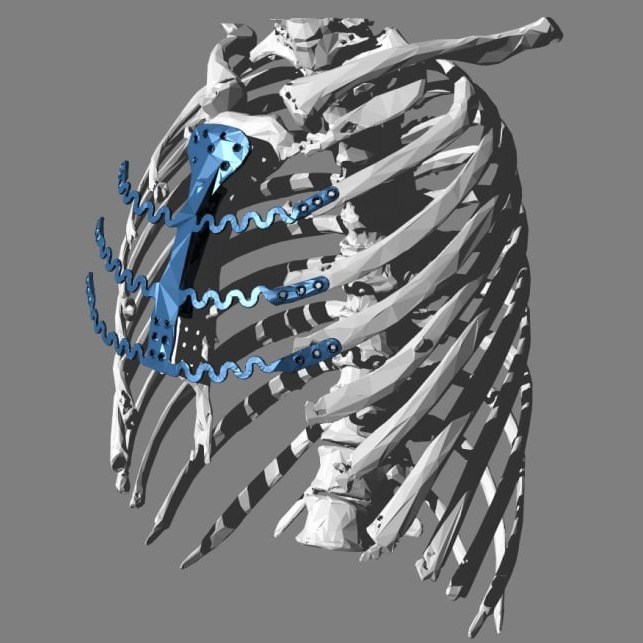

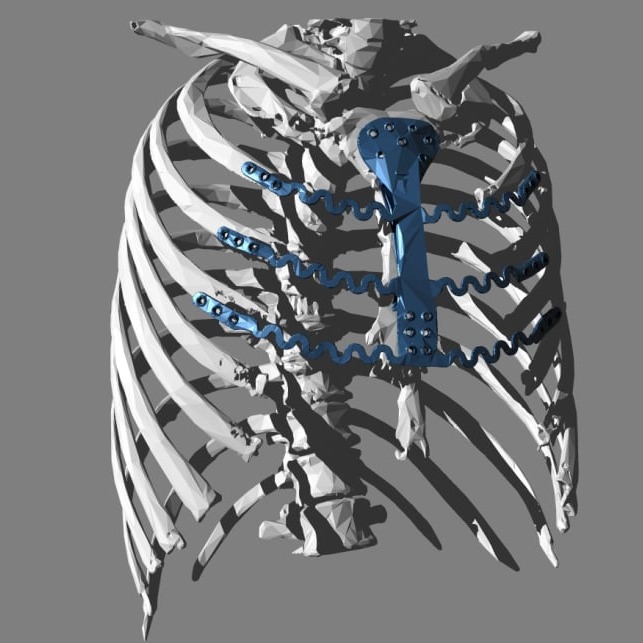

Adaptia partnership with MT Ortho Srl Italy provide a range of customized surgical implants for supportive treatment of deformities, fractures and defects of the chest wall.

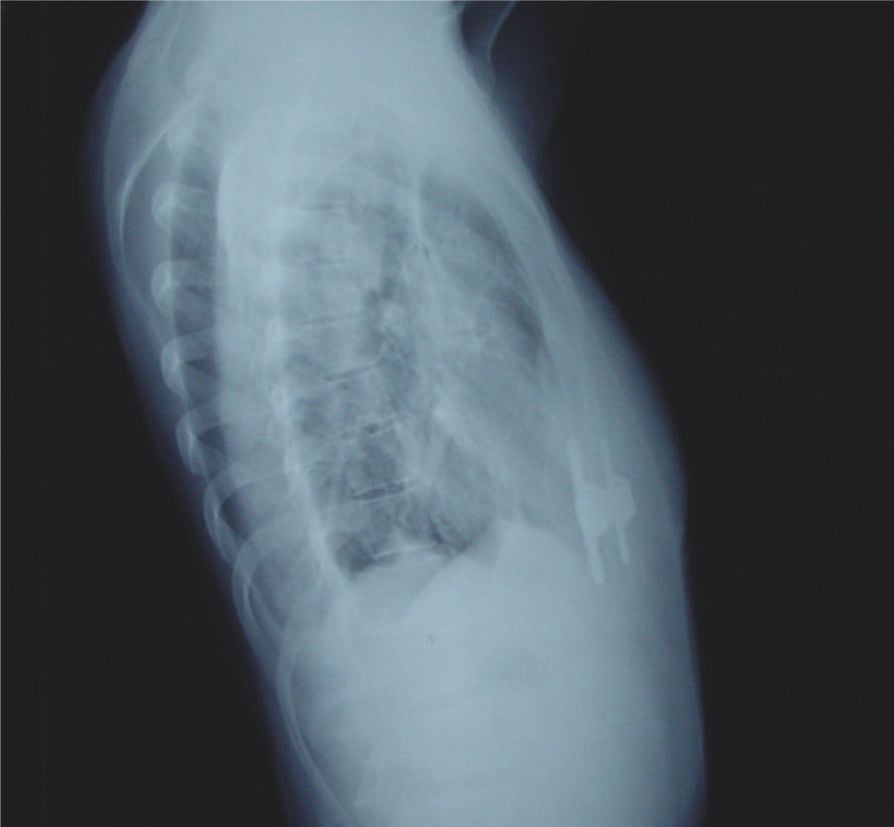

With the aid of the ARES-TR implants, osseous structures (sternum, ribs, etc.) can be re-fixed after surgical transaction, fractures can be stabilised, an

Our expertise originates from a long experience in studying challenging bone and joint conditions and looking for the most suitable tailored solutions to treat them.

Every clinical case is unique because every patient is unique. As far as we can, we will provide surgeons with the most specific solution for each patient.

Additionally, the human body has outstanding self-healing capabilities. We will always choose less invasive, tissue sparing surgical solutions, provided that such solutions are safe and effective.

When standardized solutions cannot guarantee optimal treatment, Adaptia can help identify, design and manufacture a custom-made solution for each patient.

With our partnership with MT Ortho Srl Italy we design and manufacture clinically validated, high-quality, cost-effective patient-specific solutions for thoracic surgery.

Our technical background and clinical expertise allow us to use porous metal and biopolymer 3D printing to support surgeons in finding patient-specific solutions in a wide variety of challenging medical conditions.

The procedural complexity of chest wall reconstruction has led to a variety of solutions, none of which, however, has proven to be optimal.

Conventional solutions have weaknesses, which, to different extents, make their advantages less attractive.

Common implant drawbacks include:

• incomplete protection (lack of rigidity/stability)

• paradoxical breathing (lack of rigidity/stability)

• respiratory distress (excessive rigidity)

• post-operative pain (rigidity, insufficient permeability)

• implant breakage (inadequate mechanical resistance)

Adaptia offers customized implants based on a patient’s CT scan and designed in collaboration with surgeons:

• implants are made of titanium alloy, 3D printed with EBM technology by our partner MT Ortho Srl Italy.

• size can range from a single rib to sternum with multiple ribs

• solid and stable structure to avoid paradoxical chest motion and protect internal organs

• flexible and extensible ribs to allow for normal respiratory mechanics

• shape mimics sound rib cage to minimize deformity

• implant options can include detachable sternum-rib connections

• prosthetic ribs can be fixed to resected ribs with claw-type fixation or cerclages in a wide variety of challenging medical conditions.

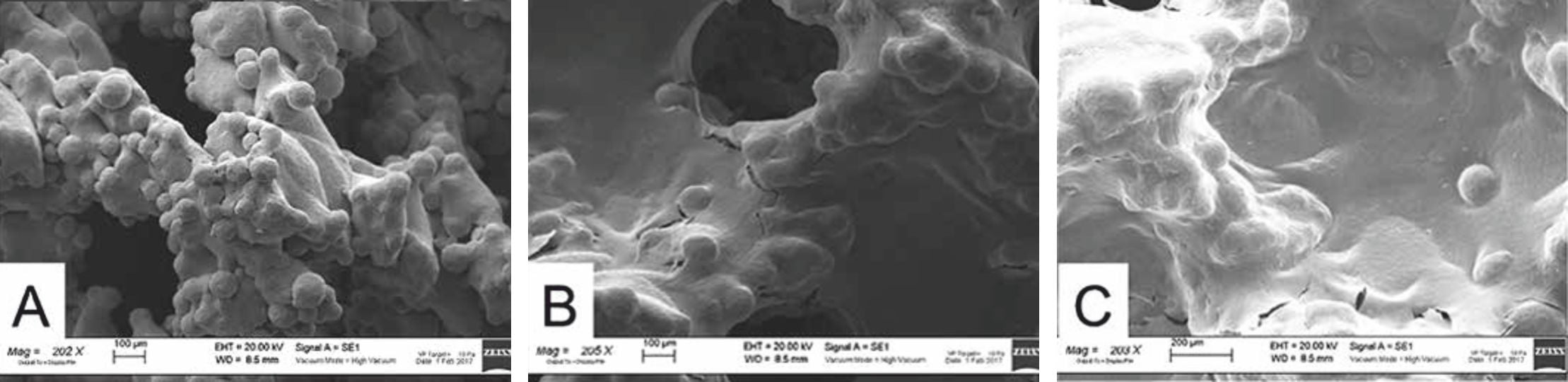

Scan using the electronic microscope of the empty cage (A) and the cage in which hASCs were sown and cultivated in a growth medium (B) and an osteogenic medium (C) for 21 days. Magnifications: A:202x. B:205x. C:202x

Via Don A. Ravizza, 42, 24060 Castelli Calepio BG

9:00 - 18:00